Sustainable Packaging Solutions: PCR bottles and Biodegradable Compostable bottles

The sustainable development of human society has put plastic packaging under increasing environmental pressure, but plastic packaging is not going to be replaced by other packaging materials because of its unique advantages. In the future, with the advancement of technology, plastic packaging materials will be utilized in a way that reduces carbon emissions and is environmentally friendly, increasing the value of plastic packaging materials. Our planet needs sustainable packaging solutions.

Custom Sustainable Packaging Options

To take the environmental responsibility, Sanle Plastics is dedicated to the development of PCR Recycled Plastic, Biodegradable, composable, eco-friendly materials for your sustainable packaging needs and we are glad to develop more eco-friendly materials further in partnership with a customer, our currently sustainable packaging material includes:

- • PCR Recycled Content(Including Ocean Bound Plastic), Less Plastic, Cost-Effective

- • PLA (Polylactic Acid) Biodegradable

- • 100% Compostable and Biodegradable Materials, Made from Plants, Plastic FREE

PCR Plastic Packaging Solutions-Reduce the Carbon Footprint

PCR’s full name is Post-Consumer Recycled material, that is, recycled material usually refers to PET, PP, HDPE, and other recycled materials, and then reprocessed for the manufacture of new packaging materials of plastic raw materials. Image point to say, waste packaging is given a second life. Statistics show that for every 1 ton of waste plastic processed, 800 kg of recycled plastic can be produced and 3 tons of CO2 emissions can be reduced.

Recycled plastics are plastic materials that are obtained again after processing waste plastics. The biggest advantage of recycled plastics is that they are cheaper than new materials and biodegradable plastics, and can be processed according to different performance needs, only a certain aspect of the properties of plastics, and manufacture the corresponding products; degradable plastics are a class of plastics whose products can meet the performance requirements of use, and the performance remains unchanged during the preservation period and can be degraded into environmentally friendly substances under natural environmental conditions after use.

Why use PCR in packaging?

Primarily because it helps protect the environment. Raw plastics are usually processed from chemical materials and reprocessing has huge benefits for the environment.

Imagine, the more people use PCR, the greater the demand. This, in turn, drives more recycling of used plastic packaging and further drives the commercial process of waste recycling, which means less plastic ends up in landfills, rivers, and oceans.

Many countries around the world are legislating the mandatory use of PCR plastics.

Using PCR plastic also adds a sense of environmental responsibility to your brand, which can be a highlight of your branding.

Many consumers are also happy to pay for PCR packaged products, making your product more commercially viable.

In short, using a certain percentage of recyclable polymers in your packaging shows your responsibility to the environment as a manufacturer, and indeed makes a substantial contribution to the cause of environmental protection. What’s not to like?

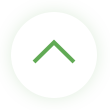

Types of Sustainable PCR plastics

Sanle Plastics can offer PCR packaging solutions based on our standard and custom HDPE, PET, and PP plastic containers in different shapes, sizes, colors, and more, PCR content up from 30% up to 100%. We are glad to be your reliable sustainable packaging supplier.

HDPE PCR: High-Density Polyethylene Post Consumer Resin, 30%,50%,100% content HDPE PCR bottles

rPET bottles: recycled PET plastics rPET bottle, up to 100% rPet

Difference between PCR recycled plastic packaging and regular plastic bottle containers:

- Odor.

PCR recycled plastic is odorless, just like regular plastic. - Color.

Compared to regular plastic, PCR recycled plastic has a slightly yellowish color. - Stability and Compatibility. Regardless of whether the container is made of regular plastic or PCR recycled plastic, the filled product needs to be tested for compatibility and stability to ensure that the product is compatible with the selected packaging container and to ensure consistent quality.

- Ductility.

PCR recycled plastic bottles are less flowable and less ductile due to the recycling process and are not as easy to mold as regular plastic. Therefore, the production design values for recycled plastic containers are different from those for general plastic manufacturing.

What is Ocean Bound Plastic?

The ocean has brought so many benefits to our lives and production, and more and more major ocean development has also harmed it. On the other hand, people have been treating it as a bottomless pit for dumping garbage and waste, while relying on its inexhaustible source of rainwater. In fact, the ocean itself is fragile and has a limited ability to clean itself. Recently, there are increasing signs that the ocean can no longer withstand continued pollution and that we need to protect it.

Ocean Bound Plastic, which is mostly extracted from the discarded plastic bottles in the ocean, The biggest advantage of OBP is the recycling, to do the recycling of marine waste.

Customize Your PCR Packaging with Sanle Plastics

Sanle Plastics is willing to develop recycled content products with customers, such as ocean-bounded bottles, and post-consumer PCR Plastic Bottles in 10%-100% recycled content, the low or high PCR content depends on the customer’s specification requirements. All the resin we use are from qualified recycled raw material supplier, their PCR resin passes the test of FDA PNC2592, ROSH REACH, European Commission Regulation, or certified by Global Recycled standard, UL 100% Ocean Bound Plastic.

We can produce recycled content products in most of our molds, such as cylinder round bottles, cosmo round bottles, square bottles, jars, boxes or custom shapes in any size and color. Our printing and labeling workshop provides brand decoration for you. The Recycled Content Plastic Products can add eco-friendly concepts to cosmetic packaging, healthcare packaging, homecare & DIY Packaging, Agricultural Packaging, Automotive Packaging, and Chemical Packaging industries.

Contact us to custom your PCR bottles and Jars now

Compostable and Biodegradable Packaging

Sanle Plastics is taking a lead in China in the research and development of eco-friendly/biodegradable green package containers.

By cooperating with local universities, American laboratories, SGS ect., Sanle Plastics has trialed different biodegradable materials for manufacturing bottles, jars, boxes, lids etc. We support custom 100% biodegradable products. The biodegradable plastic species include light degradable plastics, biodegradable plastics, biodegradable plastic, and other light degradable plastics.

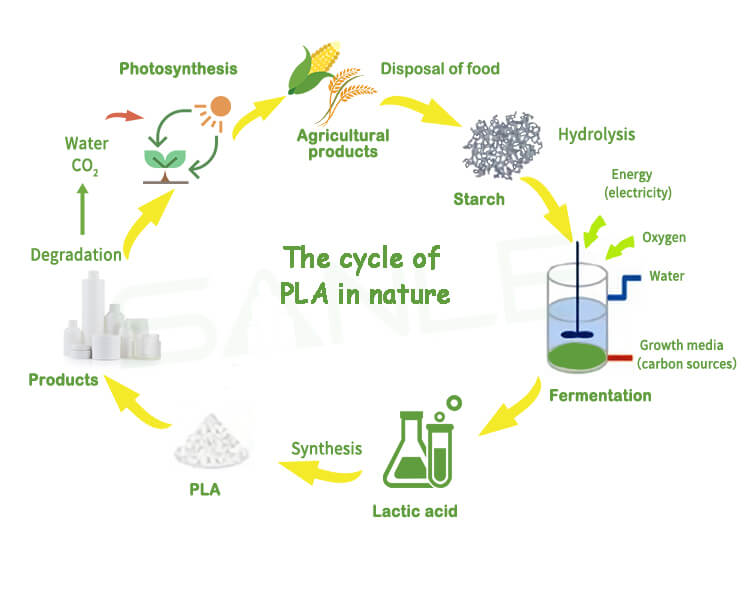

PLA (Polylactic Acid)

The PLA (Polylactic Acid), PLA is a biodegradable and bioactive compostable polymer derived from renewable sources such as corn starch, cassava roots, chips or starch or sugarcane.

Sanle Plastics has trialed these PLA in various manufacturing processes and the results to date have been encouraging although there are some limitations.

Advantage of PLA products: 1.biodegradable plant resources products degrade to water and carbon dioxide . 2. no harmful molecules that cause green house effect preferred products. 3. plasticizers in plastics can imperceptibly alter human genes but pla doesn’t.

Biodegradable Materials

![]() Our goal is to develop 3-4 types of biodegradable materials within two years that could have practical good applications and to complete preliminary research and development this year, Such as Bamboo Biodegradable Materials, and Wheat straw. Rice or more depends on the customer’s requirements.

Our goal is to develop 3-4 types of biodegradable materials within two years that could have practical good applications and to complete preliminary research and development this year, Such as Bamboo Biodegradable Materials, and Wheat straw. Rice or more depends on the customer’s requirements.

Common plastics take four to five hundred years or even thousands of years to degrade, which poses a serious burden and pollution to the environment. The biodegradable material we have chosen is environmentally superior and also has the application excellence of common plastics.

It can be 100% biodegraded under natural conditions and completely degraded to carbon dioxide and water within 12 weeks of composting time without residue; meanwhile, it has passed the heavy metal content test under EN13432 and ASTM D6400 standards, which proves that the material is very friendly to the environment, ecologically recyclable, does not contain plasticizer ingredients, non-toxic, and is a completely green material, and has a very wide range of applications, and can replace Plastic processing of a variety of products.

In addition, it would be great if we could develop this further in partnership with a customer, welcome to contact us to further discuss.